Types Of Poultry Houses

Generally, four types of houses are found to follow among the poultry farmers. These are:

- The free-range or extensive poultry house system

- The semi-intensive poultry house system

- Folding units poultry house system

- Intensive poultry house system

|

| poultry-house-system-types |

Intensive system are two types:- Deep litter poultry house system

- Cage poultry house system

1. Free-range or extensive system

The free-range system of poultry housing refers to the method of housing birds so that they have the opportunity to roam around the farm. The free-range poultry housing system is, in fact, the oldest system of housing birds in poultry farming.

It is the oldest method of poultry rearing. Generally, a very small number of birds (say, maximum of 10-12 birds per farmer’s family) are reared in this system, though in totality a huge number of birds are reared in this system.

|

| Free-range or extensive system poultry housing |

Advantages of Free Range Poultry house

- Free-range poultry housing requires less capital investment to construct.

- Feed requirements are less since birds can consume a fairly good amount of feed from grassland.

- This system helps to maintain fertility as the bird droppings mix with the soil.

- So, instead of confining the birds to an enclosure for 24 hours, they have at least a part of the day to roam freely outdoors.

- This system is perfect for poultry farmers who own a very large portion of land.

- One of the features of a free-range pen is the provision of shelter, greens, feed, water, shade, etc. for the birds.

- In this type of housing system, the birds get most of their food by searching around the farm.

- Mostly, the birds feed on herbs, seeds, and insects.

- Free-range poultry housing is relatively cheaper to construct because the shelter only requires temporary roofing supported by poles.

Disadvantages Of Free-Range Poultry House

- It will be difficult for you to apply scientific management practices in this system.

- You may lose poultry eggs when the birds lay their eggs inside the dense grasses in the free-range.

- Many farmers experience a lot of losses in this system due to predatory animals.

- Mechanism of Free-range poultry house

- In this system, birds are kept free during day time and they take shelter in a house during the night. The rearing of birds in this system is apparently profitable as birds find an appreciable amount of feeds in the surroundings during the daytime. This method is not suitable for commercial purposes.

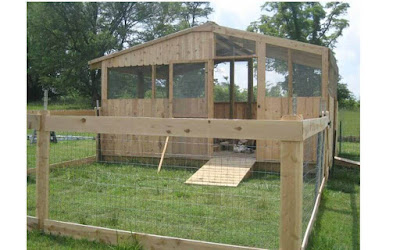

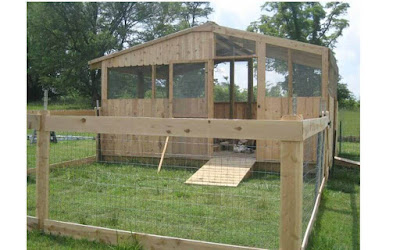

2. Semi-Intensive Poultry Housing

The semi-intensive poultry housing system is a system that is common among small-scale poultry farmers. This system of poultry rearing is partly free-range and partly intensive type. In this system, there is a poultry house followed by a run.

|

| Semi intensive poultry housing |

Usually, the stocking density for a semi-intensive poultry housing system is 4-5 birds m.sq. in houses.

Advantages of the semi-intensive poultry housing system

- It is a more economical use of land in comparison to the free-range system.

- To an extent, you can apply scientific management operations in this system.

Disadvantages of the semi-intensive poultry housing system

- High cost for fencing.

- Need for routine cleaning and removal of litter material from the pen.

Structure and advantages

The run is a small land surrounded by wire mesh and attached to the poultry house. The birds spend the daytime in the run and take shelter in the house during the night. The approximate floor space per bird is 3-4 sq ft for the house and 150-200 sq ft for the run area.

3.Folding units housing

The general theme of this system of poultry rearing is the same as that of a semi-intensive system. Here also, there is a poultry house followed by a run. The whole area of the run is enclosed by wire nettings. But the space requirement is less and the total poultry unit can be shifted from one place to another.

|

| Folding unit system chicken house |

Advantages of the folding unit of poultry housing

You spend less in feeding the birds as they pick most of their food from the range.

Just like in the free-range system, this method also helps to fertilize the soil also.

Disadvantages of the folding unit system

You have to carry food and water to the birds and bring them back each time.

This system requires some extra labor to move the fold units around every day.

It is more expensive than the previous two housing systems.

Structure and advantages

Hence the name folding unit. One can keep a small number of birds in this system on the roof of their house with sophistication. The approximate floor space per bird is 1 sq ft for the house and 3 sq ft for the run area, i.e., total of 4 sq ft per bird. So, a folding house unit measuring 20ft x 5ft is suitable for 25 birds.

4. Intensive System Housing

This system is the most efficient, convenient, and economical system for modern poultry production with huge numbers. Commercial poultry farming is done only with this system. There are different types of intensive poultry housing systems.

- Deep litter system

- Slated or wired-floor system

- Combination of the slatted floor and deep litter system

- Aviaries

- Cage system or battery system

A) Deep litter system

This system is widely used for scientific and successful poultry farming. It is very popular for small as well as large units of commercial poultry farms. In another word, it is known as the deep litter poultry system with a chicken coop.

|

| deep litter system |

Requirements for deep litter system

- The floor of the chicken house with bedding or good litter materials.

- A good litter material for your poultry farm could be straw, sawdust or leaves to the depth of 2-3 inches.

- The essence of the litter materials is to prevent the direct contact of the birds with the bare floor.

- This type of poultry house saves labor and time in the frequent cleaning of chicken droppings. However, it needs periodical stirring.

- Bird density for the deep litter system is about 4-6 birds per square meter.

- There is easy access to feed, water, and egg collection.

- With low masonry walls set on a concrete floor and wire mesh on the upper part of the walls, the building excludes rats and birds.

Positive Points

- This system maintains the welfare of birds.

- The manure from the deep litter system is useful for crop and vegetable farming.

- Birds tend to suffer lesser nuisance from flies in comparison to cage systems.

- The bacterial action on the litter in this system makes Vitamin B2 and Vitamin B12 available to the birds.

Negative points

- Because of the direct contact between birds and litter, bacteria and parasitic diseases may be a problem.

- Respiratory problems may emerge due to dust from the litter.

- The cost of litter is an additional expenditure on production cost.

- Faults in ventilation can have more serious consequences than in the cage system.

- Structure

- Birds are kept in large pens of up to 250 birds in each house. The floor of the house is covered with dry litter materials up to the depth of 3 inches in broiler and 6 inches in the layer house. Rice husk, sawdust, wood shavings, chopped straw, dried leaves, ground nutshells, etc. may be used as litter material as per the cost and availability.

Floor Requirements

The minimum floor space requirement under this system of management is 1 sq ft per broiler and 1.75 sq ft per layer chicken. However, the floor space may be increased to some extent in the summer months.

B) Slatted or Wire Floor Poultry System

When you don’t want to use a deep litter system, you can opt for slatted or wire floor poultry housing.

|

| Slatted or Wire Floor Poultry System |

General Characteristics

- You can build the house on treated wooden piers 0.8 to 1m above the ground.

- This system allows a lot of ventilation into the house and is easy for removing chicken droppings.

- The stocking for this system can be 6 to 8 per square meter.

- You may decide to roof the building with a thatch roof or corrugated iron roof.

- If you use the iron roof for the poultry pen, then you need to put some insulation under the roof.

- Because of the size of this type of building, feeding, watering & egg collection is done from outside the house.

- Cooler houses but expensive & suitable for the adult bird only

Advantages of the slatted or wire floor poultry housing system

- Birds in this system take less floor space per bird when compared to the solid floor system.

- There is no need to provide any form of litter or bedding.

- It is easy to collect manure as the chicken droppings pass through the openings on the wire floor.

- The chicken house is cleaner with better sanitation.

- You will have big savings on labor costs using this housing system.

- Because the birds do not have any contact with the soil in this system, it eliminates soil-borne infections.

Disadvantages

- It involves a higher initial cost than conventional solid floors

- This system has less flexibility in the use of the building

- You cannot easily regain feeds in case they spill because they are lost through the slots

- Flies can penetrate the pen through the openings under the floor thereby increasing fly problem.

C) Slat Floor Cum Litter System

This system combines both the features and advantages of the slat system with that of the deep litter system.

|

| Slat Floor Cum Litter System |

General Characteristics

- This system combines both the features and advantages of the slat system with that of the deep litter system.

- It has slats on either side of the house against each side wall leaving the central portion for the littered floor.

- The water and feeding trough for this system are placed on the slatted area so that wastes can drop to the floor through the slots.

- You can also have drinkers and feeders in the litter area too.

- With this system, you can maintain a bird density up to 5-7 per square meter.

- This system is actually good if you are producing broilers or going into the production of eggs for hatching.

- In the case of the latter, you will need to provide nest boxes on the litter area for the hens.

Advantages

- More eggs can be produced per unit of floor space than all solid floors.

- Fertility is better with the slat cum litter house than with the all-slat house.

Disadvantages

- This system is difficult to manage

- The initial housing investment is higher with the slat cum litter house than with the all-litter house.

- The separation of birds from the manure beneath the slats commonly results in fly problems.

D) Multi-tier System or Aviaries

The aviary system is considered the best non-cage alternative to cage systems for large-scale egg production. This is because it allows the housing of large flocks, ensuring excellent production results and low mortality. It also offers more space and opportunities for the birds to perform highly-motivated behaviors. The aviary system is also called a multi-tier system.

|

| Multi-tier system |

General Characteristics

- The tiers are the most typical feature of the spacious character of the aviary and provide living space at several levels.

- Because of the multi tiers, the hens can disperse across several levels.

- The tiers can be as high as 4 tiers.

As a result, it increases the total usable surface, thereby enabling higher stocking densities per square metre ground floor surface.

That’s approximately 18 hens per square metres compared to floor housing.

E) Cage or battery system housing

It is the latest system of poultry rearing. Floor space requirement for birds is the least in this system.

|

| Cage system poultry |

Floor space requirements

Generally, the breadth and height of the cage are 1 foot and 1% foot respectively; and the length depends on the number of birds to be kept in the cage. However, it is better not to keep more than 10-12 birds per cage.

Structure of Cages

The birds are confined in a cage just large enough to permit limited movement and allow them to stand and sit comfortably. The cage is made up of strong galvanized wire and a tray is fixed underneath the floor for the collection of droppings. The feeder and waterer remain outside the cage.

|

| Cage system poultry |

Types of Cages in Poultry

The cages may be of different types. these are

- Californian type

- Three-tier 01′

- Battery cage

- four tier type, etc.

Positive Points of the cage method of poultry housing

- It is difficult for the birds to pick up pathogens that will cause them infections.

- In this method, there is no wastage of space and food.

- It is also difficult for disease to spread in the cage system of poultry farming.

- You can easily identify chicks that are victims of cannibalism and remove them. Cannibalism is a situation in poultry farming in which a bird pecks at another bird.

- In the same way, you can also identify birds suffering from infectious diseases and isolate them for treatment.

- The system requires less labor.

- There is less cracking of eggs in this system as the birds cannot perk on the eggs.

- It is easy to collect eggs in this method.

- Also, the mortality rate is less in this system.

Negative points of the cage system of poultry housing

- It is difficult to clean the individual cages and dispose of the manure.

- Food distribution may not be accurate depending on the consumption of the birds in the cage.

- The birds are frequently subjected to a disease called cage layer fatigue. The bird lies on its side giving an impression that it is affected with paralysis. Hence, this is referred to as cage paralysis or cage layer fatigue. It may be due to Calcium and Phosphorus deficiency but the exact reason is not known.

- It involves a very high initial investment cost.

- Handling of manure may be a problem and generally, flies become a greater nuisance.

- The incidence of blood spots in eggs is more.

- In the case of broilers, the incidence of breast blisters is more, especially when the broiler’s weight is more than 1.5 kg.

Advantages of intensive poultry Housing

- It does not require a very large expanse of land as in other systems of poultry farming.

- You can easily site your poultry farm close to a market area.

- This poultry housing system makes it easy for day-to-day management.

- The production performance is higher as the birds tend to save more energy because of the restriction in their movement.

- With this system, you can easily and accurately apply scientific management practices like breeding, feeding, medication, culling, etc.

- Another advantage of this system is the ease of identifying, isolating, and treating sick birds.

- As a result, you can easily control the spread of disease in this system.

Disadvantages of intensive poultry Housing

- This method affects the welfare of the birds as a result of the restriction of movement.

- There is also a limitation on the birds to perform natural behavior like roosting, spreading wings, scratching the floor with legs, etc.

- You have the responsibility of providing all the nutrients the birds require to avoid nutritionally deficient diseases. This is because the birds do not have access to sunlight and natural feed sources.

- Even though it’s easy to control diseases in this system, the chances for spreading diseases are more. This is because of the clustering of birds, especially in the litter system.